Save time with Fuji’s new steel milling machine

Clean weld seams quickly and easily

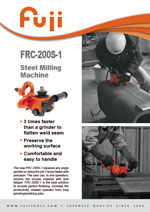

Fuji launches FRC-200S-1, an innovative mobile steel milling machine, which cleans and removes weld seams up to three times faster than typical grinding practices. The new machine enables metal working operators to save significant amounts of time and associated costs with weld removal, so they can ultimately improve productivity.

Fuji is leading the way with this new milling technology, which is the first of its type on the market powerful enough for heavy duty applications, yet compact and comfortable enough to be used by one worker. The FRC-200S-1 is suitable for traditional heavy metalworking applications where two large steel plates are welded together, such as those found in the rail industry, shipbuilding and bridge and road construction.

Weld seams are usually cleaned using a grinder to remove weld beads. However, grinding them on large steel sheets is typically a tough and time-consuming process since the whole sheet needs to be worked on – not just the weld joint.

The new steel milling machine makes the job much easier and is more precise than grinding. The FRC-200S-1 is a precision cutting tool, and after quickly setting the working depth, operators can remove the weld seam easily in one pass, rather than have to repeatedly ‘scratch’ the metal by grinding it, and without damaging the surrounding surface. This also reduces operator fatigue.

Customers were demanding the same high performance they achieve with our aluminium milling machine but for steel applications. So, we set about designing a tool that would work with steel, and are excited to bring to the market this novel machine that is the first to combine high power with low weight and small size, that helps operators to reduce time while improving their working conditions.

Clément Baylion, Global Product Marketing Manager at Fuji

FRC-200S-1 is powerful, with a governed motor of 1,000W at 4200 rpm to deliver constant speed for maximum cutting speed. It is exceptionally easy to use; it features a large dial for establishing and adjusting cutting depth and once it is set up, the user simply has to push the tool with minimal effort. It is also extremely easy to guide. The machine features metal wheels with high quality ball bearings, a visual guide to centre the work, and a roller guide to ensure only the seam is cut.

FRC-200S-1 is powerful, with a governed motor of 1,000W at 4200 rpm to deliver constant speed for maximum cutting speed. It is exceptionally easy to use; it features a large dial for establishing and adjusting cutting depth and once it is set up, the user simply has to push the tool with minimal effort. It is also extremely easy to guide. The machine features metal wheels with high quality ball bearings, a visual guide to centre the work, and a roller guide to ensure only the seam is cut.

The milling machine is ergonomic and comfortable to hold with a natural handling position. It has large handles for controlled movements and is well balanced with the weight of the tool doing most of the work. Furthermore, the machine is easy to maintain and clean, since the metal chips can be removed simply.

Designing a tool of this type was no easy feat. It requires great expertise – and our engineers have risen to the challenge, cutting tools only work at the right speeds. The FRC-200S-1 combines high power with a governed motor to provide high torque required for the cutting process while maintaining the torque level in different working conditions. Cutting steel also creates a large reaction force. The FRC-200S-1 is designed to create a marginal reaction with optimal cutting speed and it provides the perfect finish for final sanding, assembly and painting.

Clément Baylion, Global Product Marketing Manager at Fuji