Foundries

Foundry parts making requires a fast and precise cleaning of excess material. Nowadays, parts are becoming more and more complex and cleaning is a key operation for the rest of the production.

To ensure the success of this operation, you need to rely on skilled workers. The operator brings the highest value to the job and it will drive the quality and efficiency of the full operation. To support this task, the tool used to remove the excess material must bring performance and more importantly, comfort and ergonomics to the operator.

Workers can grind up to 5 hours a day in some cases so having a comfortable tool to work with is essential for them as well as for the main efficiency of the operation.

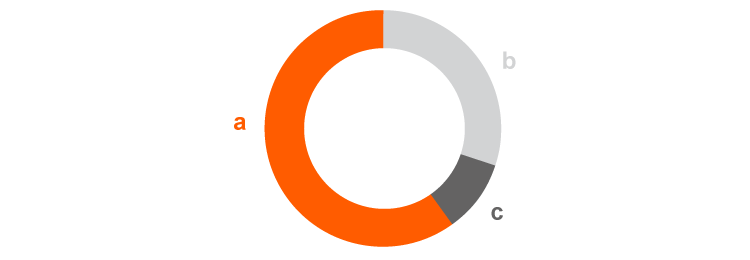

How are the operation costs of cleaning parts out of a mold split?

a – Labor 60% / b – Abrasive 30% / c – Tool 10%

Contrary to one might think, the tool cost doesn’t represent the biggest value of the operation but it can have a high influence on the cost of labor if the operator cannot work for long period of times and has to stop frequently.

Increasing your tool’s spending is a real investment. If we look at an example, increasing your tool’s cost by 30% to make operators feel comfortable at work is compensated right away just by a productivity gain of 5%.

As a leader and expert in the material removal within foundries, Fuji can help you optimize your operations by recommending you the right tool for the job.

Contact the Fuji team for a demonstration |

Discover the right tool for your application |